Why Use GPS Tracking for Your Assets?

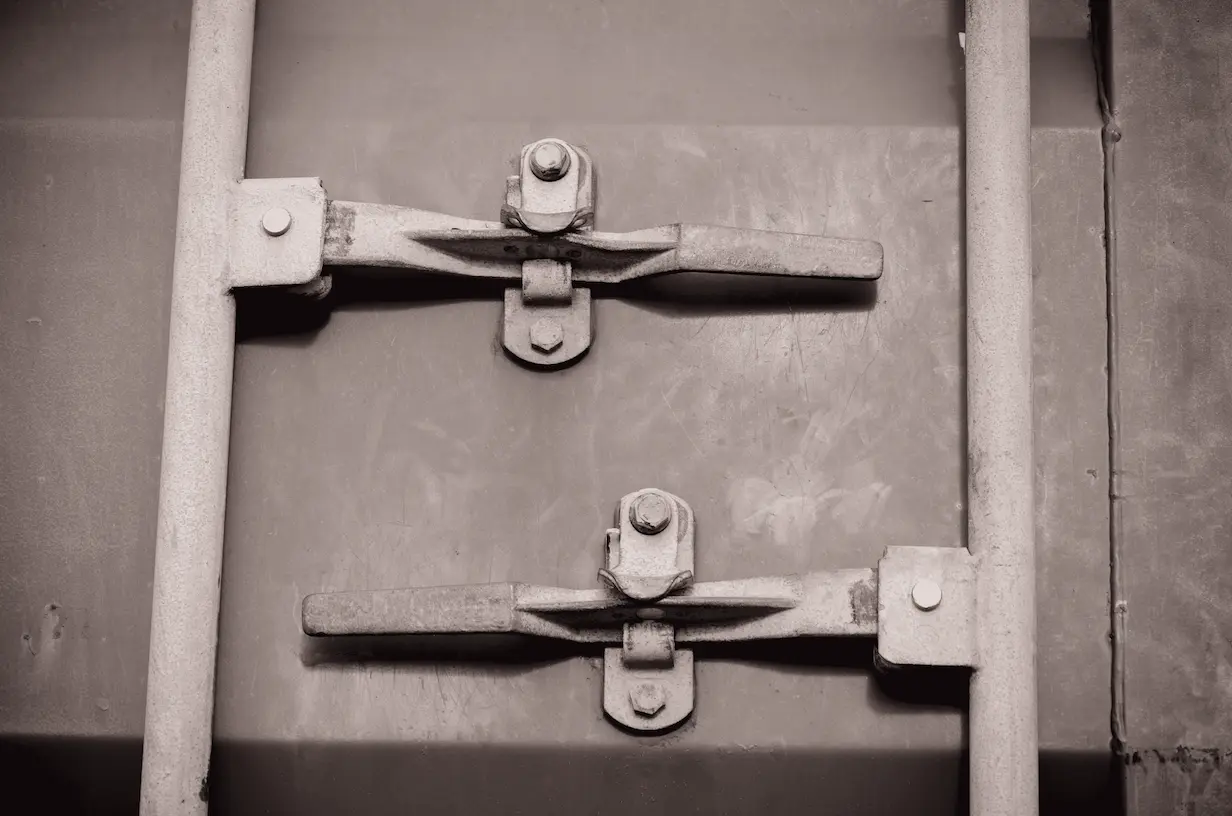

Trailers, heavy construction equipment, mining equipment and much more

Losing something is never fun. It wastes time, costs money to replace, and can cost you in lost work or lost customers. When you track your assets and equipment, it makes it much faster and much less expensive to recover them.

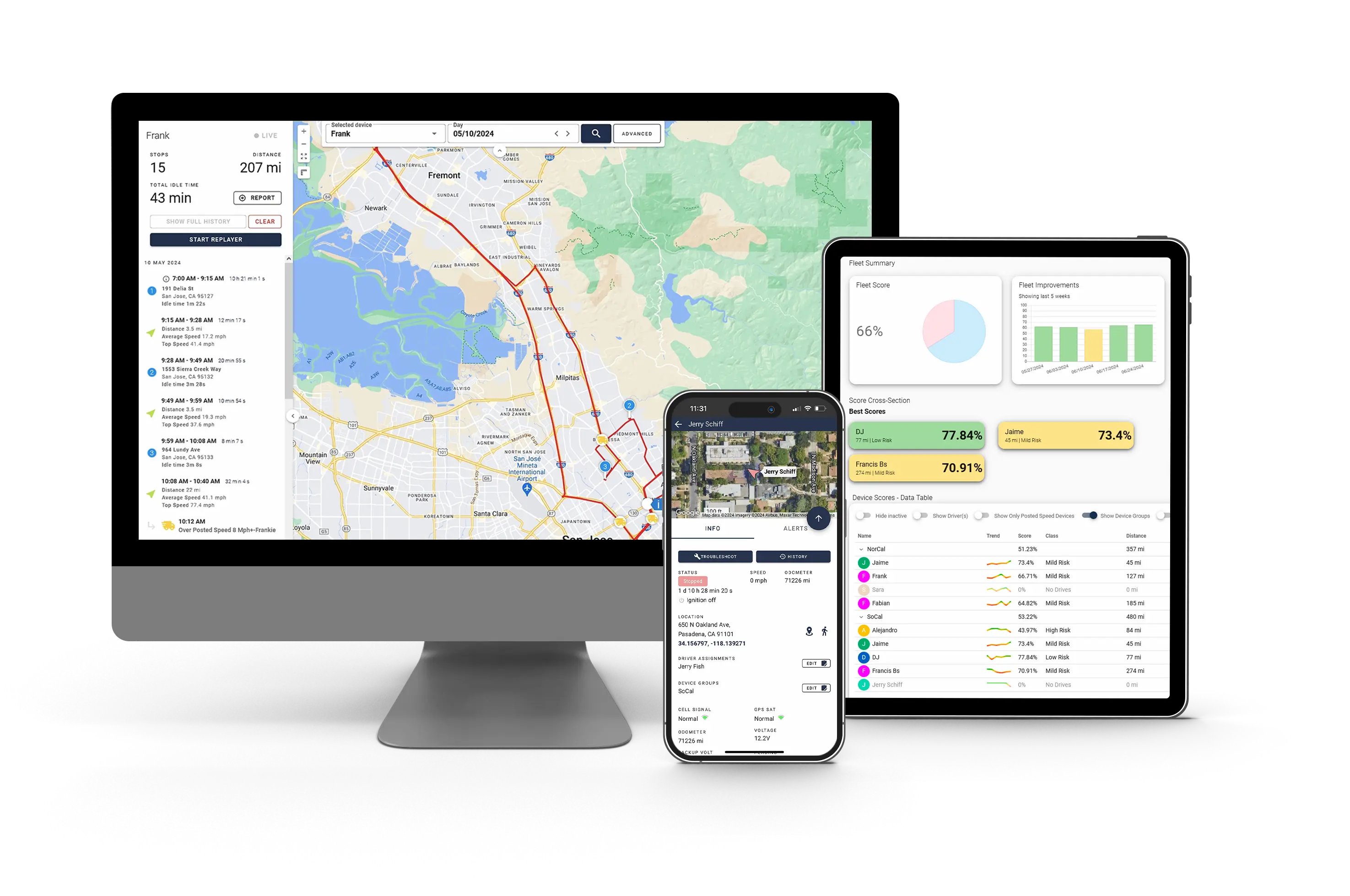

With One Step GPS, you can track and protect all of your construction equipment, trailers and assets in inventory. We offer fully customized, or straight-out-of-the-box solutions for maximum visibility, effectiveness, security & recovery.

With an easy-to-use, interactive dashboard, custom alerts and mobile apps you can monitor equipment location, usage, unauthorized use and much more.

One Step GPS equipment tracking does more than give you peace of mind. It increases efficiency. Here are some of the benefits our trackers provide:

Asset Tracking Device Options

Powerful 3rd Party Integrations

Equipment Tracking

Several Benefits of GPS Tracking on Equipment

How much does it cost?

We've spent an amazing amount of time and effort to offer a premium product at this low price. These are premium GPS tracking devices from top manufacturers. Our pricing is unheard of in the GPS tracking industry.

$13.95

per month, no contract required

Simply pay first month and one month refundable security deposit at sign up, plus an activation fee of $20 or less, depending on the number of devices.

If, for any reason, you find the service is no longer a fit for your company, you can cancel with NO penalties (device must be returned at end of subscription term).

We're so confident that you will find this product invaluable, that we offer a 100-day, full money back guarantee.